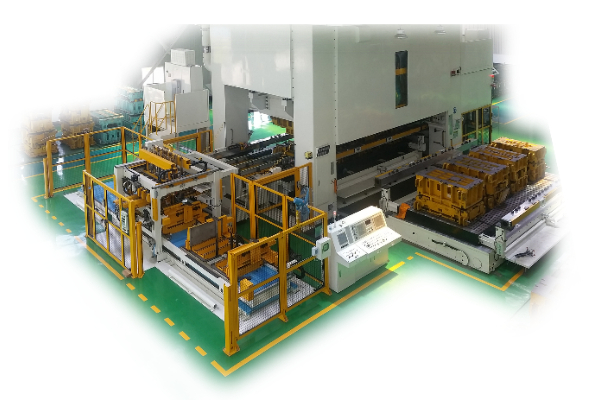

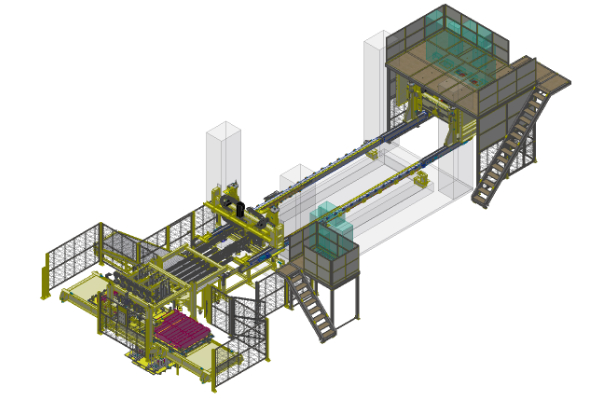

TRANSFER PRESS AUTOMATION

_3D Servo-Transfer

为了使多工序成型产品在模具以同一间距的顺序排放

用排放好工具的机械臂 Y(捕捉), Z(抬起), X(移送)方向运行,使材料按顺序移动的同时成型。

此时机械臂是和冲压机的滑块运行完美结合同步运行。

机械臂运行的驱动部(Driving Feed Bar )与 工具摆放的中间部分( Center Feed Bar)分部。

有台面的冲压机情况,在模具交换时机械臂自动分离并安置在装置在台面上的支架和台面一起出来,在更换模具时一起更换工具.

为了使模具更换,机械臂会有自动 连接/断开 及 安置/准备。

根据冲压机的磁村及形状有多种型号来选择

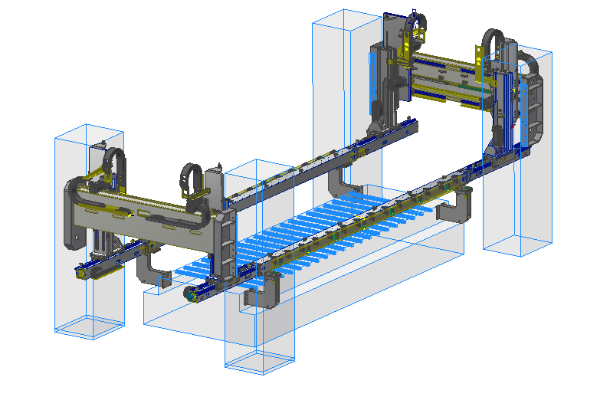

“ 2-Clamp/Lift/Feeder units hung on side-window”

2-Clamp/Lift/Feeder units

Hung on side-window

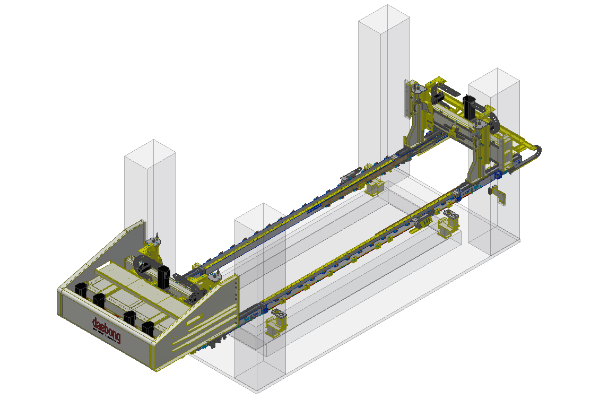

2-Clamp/Lift + Feeder units

Hung on side-window

“ 2-Clamp/Lift + Feeder units hung on side-window”

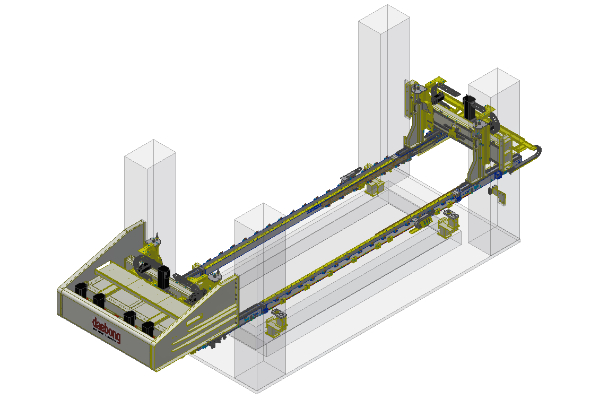

“ 2-Clamp/Lift/Feeder units hung on Front & Rear-Window”

2-Clamp/Lift/Feeder units

Hung on Front & Rear-window

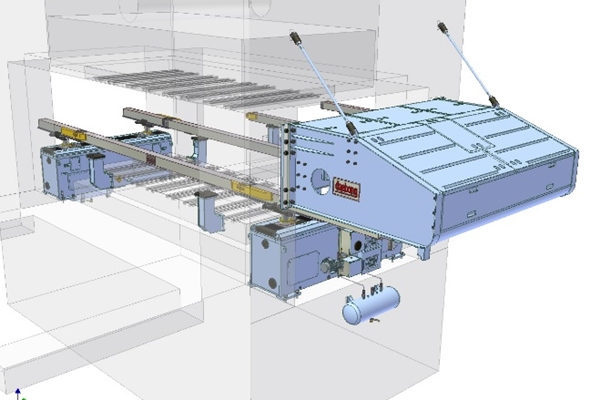

2-Clamp/Lift + Feeder units

on the Left & Right Bed

“ 2-Clamp/Lift + Feeder units on Left & Right Bed”

Auxiliary equipment for 3D transfer:

Feeder, double material detector, ejector, oiler, cleaner, material centering and stacking equipment.

Destacker & 3D transfer

Destacker varies depending on type and size of material, user space, press condition, etc. Generally there are gantry loader type and belt conveyor type.

Belt Feeder type Destacker with Programmable Vacuum pad for Aluminum and Steel Blank

Gantry type Destacker with exchangeable tools and coil line for Aluminum and Steel Blank

Coil line with Shear for Transfer and Progressive job for Aluminum and Steel coil