PRESS + PRESS

Multi-process transfer line may need a large press when the product requires intense level of multi-forming sessions. The large press, on the other hand, could be inefficient if the line runs for small and simple products.

As always, DAEBONG Engineering suggests solutions below.

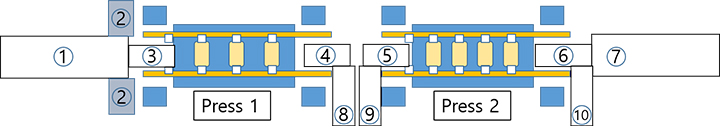

Dual press installed in a line as one long bolster including material feeding (①②③⑥⑦), connecting (④⑤), product ejecting(⑧⑨) system.

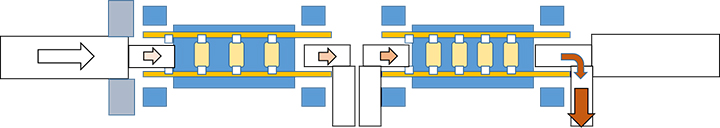

1. Dual presses are synchronized as one line for heavy load or multi-forming processes.

Case 1 : : Coil line → Progressive Process

→ Transfer forming Process

Case 2 : Coil line → Blanking process

→ Transfer forming Process

Case 3 : Coil line → Shearing Process → Transfer forming Process

Case 4 : Destacker → Transfer

forming Process

2. Each press works separately when the work load and the

number of forming processes are less.

-

Case 1 : P1(Progressive / Transfer) with coil line

+ P2(P1(Progressive / Transfer) with coil line -

Case 2 : P1(Transfer) with Destacker

+ P2(P2(P1(Progressive / Transfer) with coil line

With our DTL solutions, presses can be used either as transfer, progressive or combination of both.

DAEBONG has a variable experience with link-work for dual presses. We suggest reasonable solution depends on your site condition.